Promo Text

SUPERB FACTORY SPACE

SKILLED EMPLOYEE

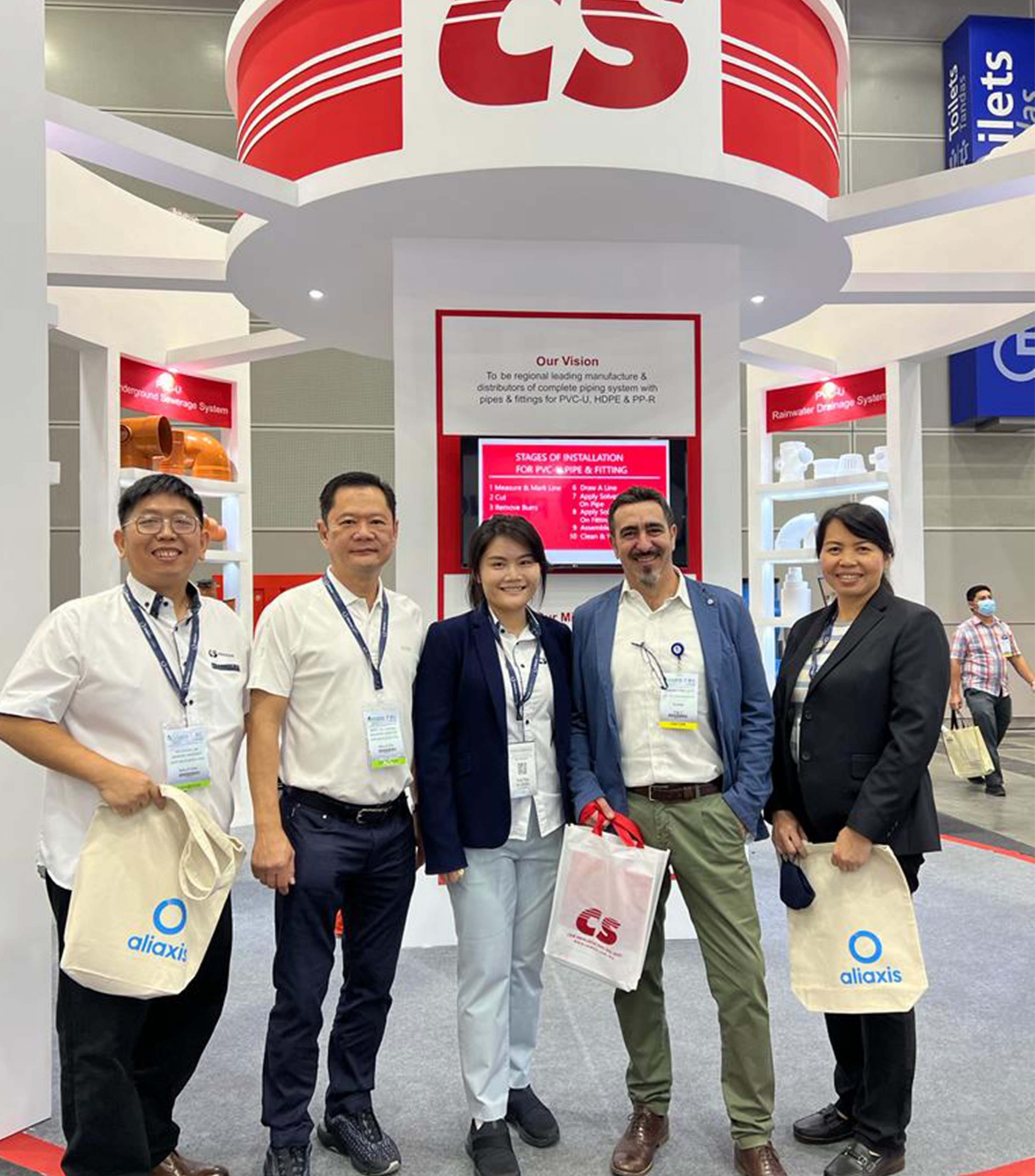

EXCELLENT CUSTOMER SERVICE

Result that Speaks

Result that Speaks

We've been delivering unique, robust, and great result to local and international infrastructure builders since 1992. and our list is still growing with the ever-expanding sectors worldwide.

Newsletter

Subscribe To Newsletter

Sign up For Exclusive Updates.

Customer Say

Career at Cewsin

Looking for a good long term career opportunity or think you have the skill to contribute to our industry?

MoreAbout Cewsin

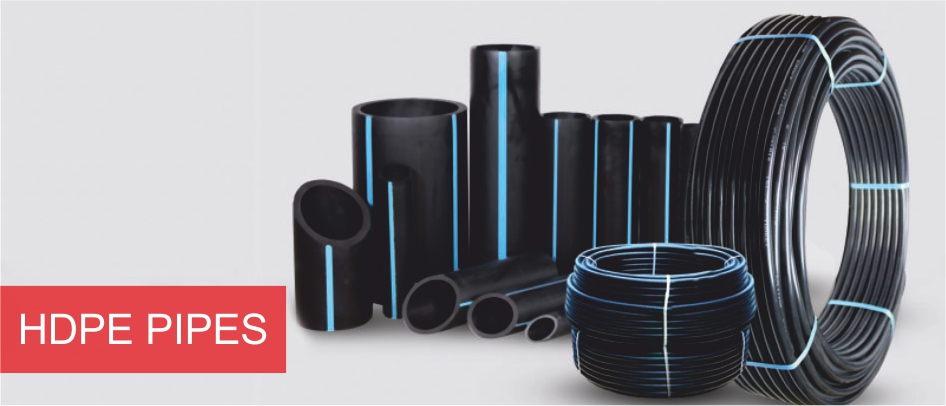

Cew Sin Plastic Pipe Sdn Bhd (Cew Sin) was incorporated on 27th June 1992 to venture in the business of manufacturing and distribution of limited range of PVC-U pipes.

Moresign of quality

Sign of Quality

We Are Certified by Professionals