INSTALLATION GUIDE

Preparation

Prepare all the needed tools and equipment for the pipe installation.

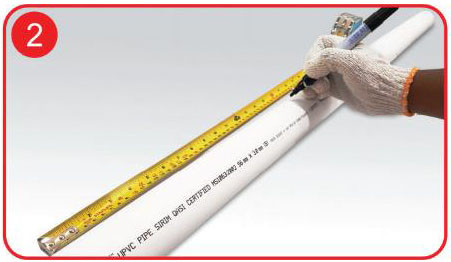

Marking

Mark the socket depth on the pipe end.

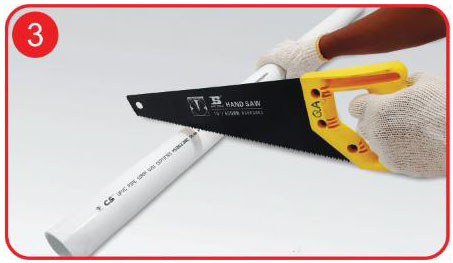

Cutting the Pipe

Cut the pipe with the proper tool, using a fine-toothed saw.

Joint Preparation

Slightly deburr the external pipe edge and break off any sharp edges.

Cleaning

Thoroughly clean all surfaces to be joined. Any dirt, moisture, oil and other foreign material will affect the joining‘s integrity.

Test Dry Fit of the joint

Insert the spigot into the socket without the solvent cement to check the fit. An interference fit should occur between 1/3 and 2/3 of full entry.

Witness Mark the pipe

Draw a line on the spigot to show the depth of the socket.

Apply Solvent Cement on Pipe

Apply an even coat of solvent to the pipe marked for joining.

Apply Solvent Cement on Fitting

Apply an even coat of solvent to the inside of the spigot or socket.

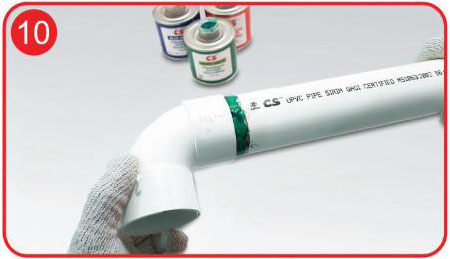

Assembly of joint

While both parts to be joined are still wet, put the spigot into the socket in a slightly twisting motion. Hold the cemented joint idle for a minimum of 30 seconds for secure adhesion.

Clean off

Wipe off excess cement from the pipe at the end of the socket. Any gaps in the cement ring around the pipe perimeter may indicate a defective assembly.